nickel-copper flexible busbar is a highly flexible electrical conductor, usually made of nickel and copper alloy materials, designed for efficient current transfer. Nickel-copper flexible busbars are used in a wide variety of industrial and power systems because they offer greater installation flexibility, corrosion resistance, and high-temperature capability than traditional rigid busbars. It provides reliable power connections in space-constrained or complex environments, and is especially suitable for applications that require frequent adjustments or installation in confined areas.

Nickel-copper flexible busbars not only have excellent electrical conductivity and mechanical properties, but can also withstand high current loads and reduce energy losses in power transmission. Its flexible nature makes the installation process easier and avoids the problem of rigid busbars that are difficult to adapt to complex environments. In addition, the nickel content in nickel-copper alloys enhances the busbar's corrosion resistance, making it particularly suitable for environments with high humidity, salt spray or severe chemical corrosion.

How to manufacture nickel-copper flexible busbars?

The process of manufacturing nickel-copper flexible busbars is relatively complex and requires strict process control to ensure quality and performance. The specific manufacturing steps are as follows:

The material is cold worked to achieve the required accuracy and the shape is molded. This step ensures that the size and shape of the busbar meets the design requirements and that its electrical properties are not damaged during bending and installation.

At every stage of production, nickel-copper flexible busbars need to undergo strict quality inspection and testing. Tests include conductivity tests, corrosion resistance tests, heat resistance tests, etc., to ensure that the product meets industry standards and is able to work stably in practical applications.

Characteristics of nickel copper flexible busbar

Nickel-copper flexible busbar has a number of notable features that make it widely used in power, industrial, and various high-end applications. Some of the key features are listed below:

1. Excellent electrical conductivity

Nickel-copper alloys have excellent electrical conductivity which ensures efficient power transmission. Compared to pure copper, nickel-copper alloys offer greater resistance to high temperatures and corrosion while maintaining electrical conductivity, making them suitable for a wide range of environments.

2. Excellent Flexibility

2. Excellent Flexibility

One of the greatest advantages of the nickel-copper flexible busbar design is its extreme flexibility. It can be bent and folded without damaging the structure of the material, making it easy to install in tight or irregular spaces. This flexibility also allows it to withstand vibration and other dynamic loads for a variety of industrial applications.

3. Corrosion resistance and high temperature resistance

Thanks to the addition of nickel, nickel-copper flexible busbars offer excellent corrosion resistance, especially in environments with high levels of moisture, salt spray, chemical exposure or high temperatures. This makes it ideal for use in demanding locations such as marine environments, power equipment, and chemical plants.

4. High mechanical strength

Nickel-copper alloys have high tensile and flexural strengths, ensuring that the busbar can work stably for a long time even in harsher environments.

5. Surface treatment and oxidation resistance

The surface of nickel-copper flexible busbars usually undergoes special treatments, such as nickel plating, which further enhances its oxidation resistance and ensures that the busbars maintain excellent conductivity after a long period of use. The surface treatment also improves the busbar's resistance to contamination and reduces the occurrence of electrical faults.

6. Accuracy and quality stability

Strict dimensional control and process requirements during manufacturing make nickel-copper flexible busbars highly accurate and ensure their reliability in all types of electrical connections. Precise dimensions and highly consistent material properties provide excellent stability and safety in power systems.

7. Compliance with industry standards

Nickel-copper flexible busbars are manufactured in strict compliance with relevant industry standards, including international standards (e.g. ISO, UL, CE, etc.) to ensure product quality and safety. Through rigorous quality testing, nickel-copper flexible busbars are guaranteed to perform consistently under high loads and frequent operation, and to meet the requirements of a wide range of power systems.

Application areas of nickel-copper flexible busbars

Due to its excellent electrical conductivity, corrosion resistance and mechanical strength, nickel-copper flexible busbar is widely used in many fields. The following are some typical application scenarios:

Due to its excellent electrical conductivity, corrosion resistance and mechanical strength, nickel-copper flexible busbar is widely used in many fields. The following are some typical application scenarios:

1.Power system

Nickel-copper flexible busbars are commonly used in power substations, power plants, distribution systems and other fields to provide reliable power transmission. Due to its ability to withstand large current loads and good corrosion resistance, it is suitable for use in harsh environments such as high temperature, high humidity and salt spray.

2. Data center and communication equipment

Data centers have very high requirements for the reliability of power transmission. Nickel-copper flexible busbar is widely used in data center power supply system due to its excellent conductivity and durability. It can effectively reduce power loss and improve system operation efficiency.

3.Industrial automation and control system

In industrial control and automation systems, nickel-copper flexible busbar is used to connect various electrical control devices, such as frequency converters and servo systems. Its flexibility can be easily adapted to complex layouts and ensure stable operation of the system.

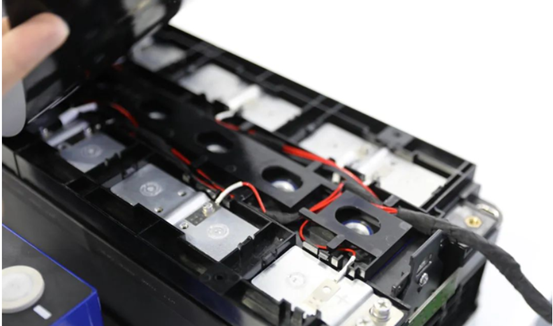

4. Automobile and rail transportation

Nickel-copper flexible busbars are used for power distribution and current transmission in electric vehicles, rail transportation and other means of transportation. Especially in electric vehicles, flexibility and high conductivity are essential to withstand high currents and ensure safe operation over long periods of time.

5. Offshore and Marine Applications

In the electrical systems of ships and offshore platforms, nickel-copper flexible busbars with excellent corrosion and high temperature resistance are ideal for use in harsh marine environments to ensure the stable operation of the ship's electrical system.

6. Solar and wind power generation

Nickel-copper flexible busbar is widely used in the renewable energy industry, such as solar power and wind power generation systems. It provides efficient power transmission, ensures stable operation of the system, and is suitable for a variety of complex installation scenarios.

7. Home Appliances and Electronics

Due to its excellent conductivity, nickel-copper flexible busbar is also used in the electrical connection of various home appliances and electronic products, such as smart home and home appliance control systems, to ensure stable current transmission.

How to design NiCu flexible busbar?

How to design NiCu flexible busbar?

When designing a nickel-copper flexible busbar, several factors need to be considered to ensure optimal performance:

1. Material selection: Choosing the correct ratio of nickel-copper alloy is critical to achieving the ideal balance between electrical conductivity and corrosion resistance.

2. Thickness and width: The thickness and width of the busbar needs to be designed according to the current load to ensure that it can carry the current while remaining flexible. This often depends on the needs of the specific application.

3. Bend radius: The bend radius needs to be large enough to avoid damage to the internal structure of the busbar and to maintain electrical performance.

4. Insulation: For applications that require insulation, it is important to select the right insulation material that has good thermal stability and shock resistance.

5. Load Requirements: The design must take into account the maximum current to be carried by the busbar to ensure that it will not overheat or be damaged under high current loads.

6. Environmental considerations: The design must take into account the temperature and humidity of the working environment and whether it will be exposed to chemicals or corrosive substances.

Why choose G and N Fortune Limited for nickel copper flexible busbars?

By choosing G and N Fortune Limited as your supplier of nickel copper flexible busbars, you will gain several advantages:

1. Professional experience: G and N Fortune Limited has many years of experience in the design and manufacture of nickel-copper flexible busbars, and is able to provide high-quality customized solutions according to your specific needs.

2. High-quality materials: We use high-quality nickel-copper alloys to ensure that the busbars have the best electrical conductivity, corrosion resistance and durability.

3. Customized solutions: We provide customized busbar solutions according to the needs of different industries to meet the special requirements of power, communication, automotive, renewable energy and other fields.

4. Advanced Manufacturing Capability: We have advanced production facilities and technical teams to ensure that each busbar meets strict quality standards and provides reliable electrical performance.

5. Competitive price: We offer cost-effective products that balance price and performance to ensure you get the best return on your investment.

6. Timely delivery: Our efficient production process and perfect logistics system ensure on-time delivery of products to meet your project schedule.

7. Customer-first service: We are always customer-centered and provide you with professional support in every step of the process to ensure that you enjoy a worry-free purchasing experience