What is an Aluminum PVC Coating Busbar?

What is an Aluminum PVC Coating Busbar?An Aluminum PVC Coating Busbar is a type of electrical conductor made of aluminum that is coated with a layer of PVC (Polyvinyl Chloride) to provide enhanced insulation, corrosion resistance, and mechanical protection. This combination of aluminum and PVC offers an ideal solution for power distribution and electrical systems where safety, durability, and cost-effectiveness are essential. Aluminum, known for its excellent conductivity and lightweight properties, combined with the protective PVC coating, ensures reliable and long-lasting performance in various environments.

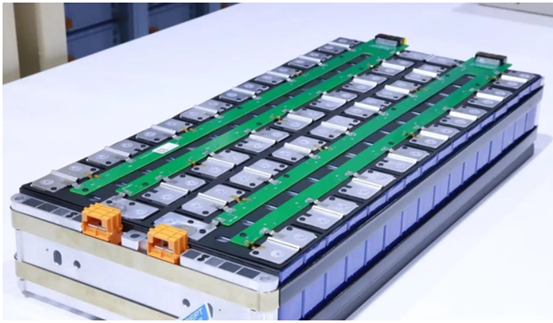

Aluminum PVC Coating Busbars are widely used in industrial applications, commercial power distribution, and electrical systems, offering both effective current transfer and safety by preventing electrical short circuits, damage, and accidental contact with conductive parts.

The process of manufacturing aluminum PVC coating busbars involves several precise steps to ensure the final product meets required standards and performs optimally. The typical manufacturing process includes the following steps:

Aluminum PVC Coating Busbars have several key characteristics that make them ideal for use in a variety of power distribution and electrical systems:

1.Excellent Electrical Conductivity

Aluminum has a high conductivity, making aluminum busbars highly efficient in transferring electrical power. The addition of the PVC coating does not compromise the electrical performance, ensuring efficient power transmission.

2.Corrosion and Abrasion Resistance

The PVC coating protects the aluminum from corrosion caused by moisture, chemicals, or environmental exposure. It also provides a durable layer that resists physical damage, ensuring a long lifespan even in harsh conditions.

3.Enhanced Insulation

The PVC coating provides excellent electrical insulation, protecting operators and equipment from electrical shocks and short circuits. It is especially important in environments where electrical safety is a primary concern.

4.Lightweight and Easy to Install

Aluminum is much lighter than other conductive materials like copper, making aluminum PVC-coated busbars easier to handle and install. Their light weight reduces the overall weight of electrical systems and helps save on installation costs.

5.High Mechanical Strength

Aluminum’s mechanical properties combined with the PVC coating provide good strength, enabling the busbars to withstand mechanical stresses such as vibration, bending, and thermal expansion without damage.

6.Cost-Effective

Aluminum is a cost-effective alternative to copper for busbars. The addition of PVC coating further improves the busbar's properties, providing a durable and affordable solution for electrical systems.

7.Compliance with Industry Standards

Aluminum PVC-coated busbars are manufactured according to international standards, such as ISO, UL, and CE, ensuring that they meet global safety, performance, and environmental requirements.

Application Areas of Aluminum PVC Coating Busbars

Application Areas of Aluminum PVC Coating BusbarsAluminum PVC coating busbars are widely used across various industries due to their excellent electrical conductivity, corrosion resistance, and mechanical strength. They are commonly found in power distribution systems, including electrical substations, power plants, and distribution networks, where they provide efficient and reliable power transfer. Their insulation properties make them ideal for residential and commercial electrical systems, ensuring safe power distribution. Additionally, they are used in industrial automation, renewable energy systems (such as solar and wind power), and automotive and rail transportation, where they support stable current transmission. Furthermore, their resistance to corrosion makes them suitable for marine and offshore applications, as well as telecommunications and data centers, ensuring reliable and safe electrical connections.

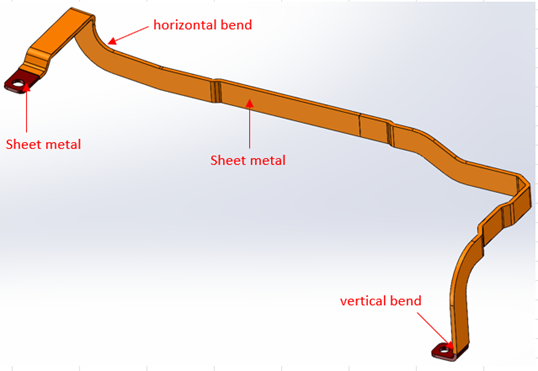

When designing aluminum PVC coating busbars, it is essential to focus on material selection, ensuring that the right aluminum alloy and PVC coating are chosen to achieve optimal electrical conductivity, strength, and insulation. The dimensions of the busbar—such as thickness, width, and length—should be designed based on the specific current load and installation requirements. The bend radius must be large enough to prevent damage to the busbar during installation, especially in tight spaces. Insulation properties should be carefully selected to meet safety standards, and the design must account for environmental factors like temperature, humidity, and exposure to corrosive substances. Additionally, load requirements should be thoroughly considered to ensure the busbar can safely handle the expected electrical current without overheating or failure.

By choosing G and N Fortune Limited for your aluminum PVC coating busbars, you benefit from the following advantages:

1.Extensive Experience

With years of expertise in designing and manufacturing aluminum PVC coating busbars, we provide reliable and high-quality solutions tailored to your specific needs.

2.Premium Materials

We use the highest quality aluminum alloys and PVC materials to ensure the best electrical performance, mechanical strength, and durability for your busbars.

3.Customized Solutions

Our team offers customized busbar designs to meet the unique requirements of various industries, ensuring that your electrical system performs optimally.

4.State-of-the-Art Manufacturing

With advanced production technologies, we ensure the highest quality and precision in every busbar we produce, providing reliable performance and safety.

5.Competitive Pricing

We offer affordable and cost-effective aluminum PVC coating busbars without compromising on quality, giving you the best value for your investment.

6.Timely Delivery

Our efficient production process and logistics ensure that products are delivered on time to meet project deadlines.

7.Customer-Centered Service

At G and N Fortune Limited, we prioritize customer satisfaction, providing professional support throughout the entire process, from design to after-sales service.